ADVANCED MATERIALS & MANUFACTURING

The University of Arizona has made notable advancements in Advanced Materials and Engineering. The Department of Materials Science and Engineering excels in research, academics, and industry collaboration. The university's pioneering work includes innovative treatments for cancer, advancements in quantum computing, and crucial developments in semiconductor technology. These efforts have positioned UArizona as a leader in modern engineering and materials science.

FEATURED STORIES

Defense Manufacturing Conference 2024: Advancing Warfighter Capabilities

Additive manufacturing advances support Army ground vehicle readiness, extend fight

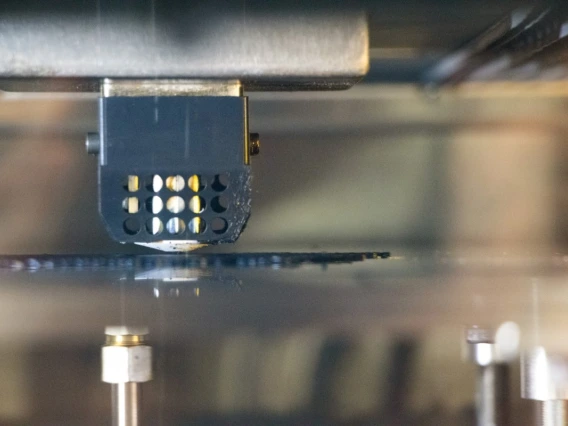

The U.S. Army's Battle Damage Repair and Fabrication (BDRF) process leverages cutting-edge 3D computer-aided design and additive manufacturing to rapidly replace damaged vehicle parts. This innovative approach minimizes vehicle downtime and preserves the lifecycle of older platforms. By partnering with various Army and manufacturing centers, the BDRF program has produced over 600 3D CAD models for on-demand fabrication, ensuring battle-worn vehicles remain mission-ready.

Interestingly, some temporary-use parts have outperformed the original ones, shaping the future of Army sustainment. This collaboration not only strengthens advanced manufacturing capabilities but also supports commercial and federal priorities, highlighting the importance of innovation and agility in modern military logistics.